To enquire about this item click the "Enquiry"

Tab below and fill out the form

Description

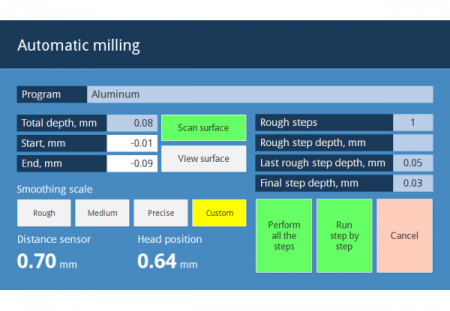

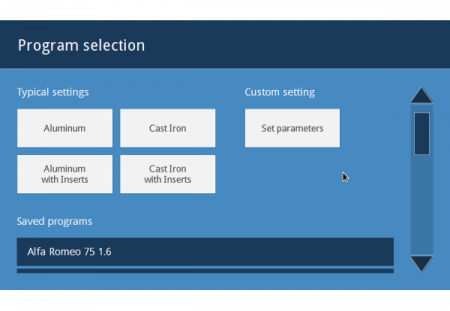

The Comec RP1400CNC head and block resurfacer has been designed for resurfacing cylinder heads and engine blocks of cars and trucks, as well as all flat surfaces requiring maximum accuracy of the contact surfaces. The construction design combines highly innovative solutions, such as a brushless motor for the automatic and precise positioning of the milling cutter plate – that is controlled by the CNC – with proven and tested features such as linear guides and recirculating-ball feed screws. The axes and the rotation speed of the milling cutter are controlled by an inverter. It is possible to monitor the feed speed. The control panel is an industrial touch screen, equipped with a simple and intuitive programming. The RP1400 CNC can be supplied with a milling cutter plate with tool-holder of CBN-PCD with a diameter of 405mm to resurface cast iron or aluminium surfaces. For heads with pre-chambers, you can use a special tool to ensure the perfect finish.

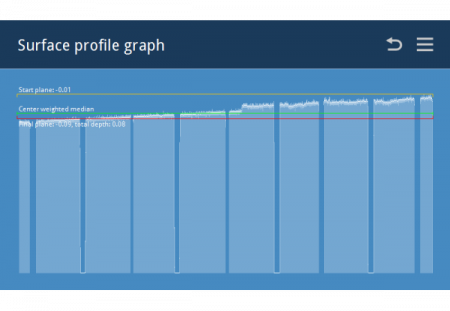

The RP1400 CNC is defined as the “Smart Resurfacer”, thanks to its laser sensor that scans the cylinder-head surfaces, thus recording their profile and automating milling operations.

Standard Equipment:

- Table and head feed with recirculating-ball screw

- Ø 405 mm milling plate with CBN insert

- Touch screen CNC control panel

- Laser sensor for scanning workpiece

- Surface profile graph

- Fully automatic cycle

- Database with preloaded working cycles and possibility to customise them

- Estimated cycle time

- Safety guard with sliding doors

- PV0160 Pair of parallel supports

- PV0021 Large clamps (2 pcs.)

- PV0022 Small clamps (4 pcs.)

- Lubricant for slides

- Wrench set

- Instruction manual

Additional information

| Manufacturer | Comec |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.