To enquire about this item click the "Enquiry"

Tab below and fill out the form

Description

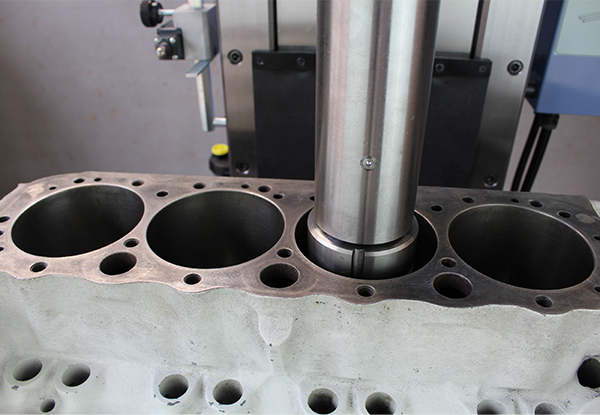

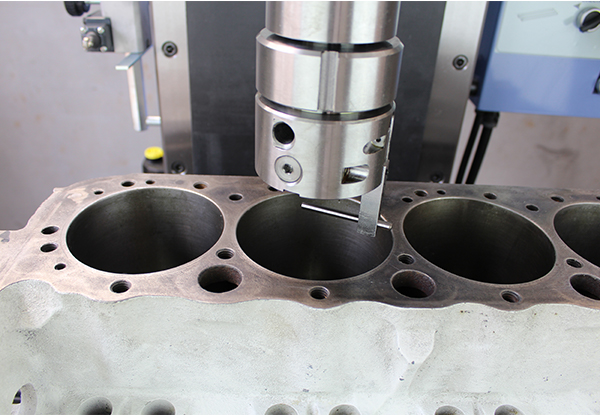

The ACF200.CNC boring machine seamlessly integrates two essential operations in the reconditioning of car and truck monoblocks—boring and smoothing—into a single, advanced system. Featuring cutting-edge CNC control, the ACF200.CNC is fully automated, significantly streamlining the reconditioning process and enhancing overall productivity.

This machine is designed to deliver superior finishing quality and precision, combining a proven mechanical structure with the latest technological innovations. The result is a highly accurate and efficient machine that performs with exceptional speed and ease. The inclusion of advanced features makes the ACF200.CNC both smarter and more user-friendly, ensuring that even the most complex reconditioning tasks are completed with optimal efficiency.

In summary, the ACF200.CNC represents a significant advancement in machine technology, offering a comprehensive and versatile solution for reconditioning operations that meets the evolving demands of modern automotive and industrial applications.

- Computer Numerical Control using LINUX Operating System and ARMv8 CPU Processor

- Precision Ball screw drives on 3 Axis

- Movements by linear railways on 3 Axis

- Brushless motors on 3 axis controlled by CNC

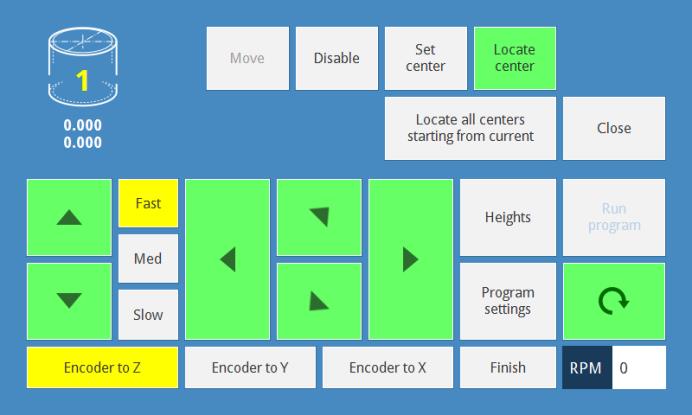

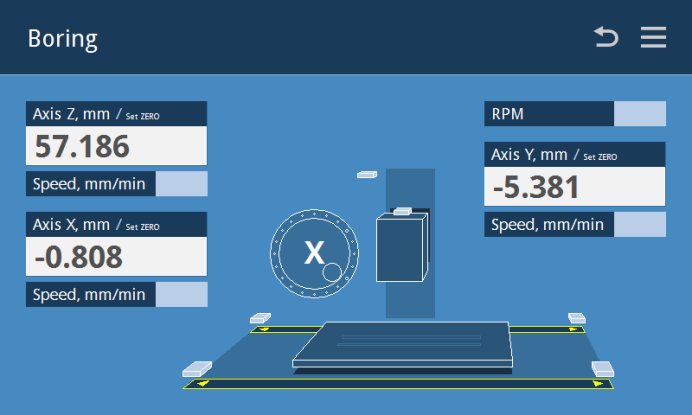

- Swing arm control panel with double touch screens

- Electronic Handwheel for manual displacement on 3 Axis (Fast-Medium-Fine speeds)

- Full automatic and programmable working modes for boring and milling operations

- WI-FI and LAN connections for support and service

- PV0160 pair of parallel supports

- PV0021 large clamps (2 pcs.)

- PV0022 small clamps (4 pcs.)

- Wrench set

- Instruction manual

Additional information

| Manufacturer | Comec |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.